Visutech, a key partner of Kyocera in the Nordic countries, specialises in providing solutions for the graphic industry market, focusing on packaging, labels, and commercial print applications. They have worked closely with OSO Hotwater, a Norwegian manufacturer of high-quality stainless steel water heaters that caters to both domestic and international markets, to address their complex printing needs. The answer from Visutech for OSO Hotwater is the TASKalfa Pro 15000c and the Plockmatic BF-450e Booklet Maker.

Background

OSO Hotwater has over 90 years of innovation and a growing product portfolio. The company manages all technical documentation internally, including printing of user manuals and installation guides. Following this innovation and growing portfolio, the volume and complexity of printed documents also increased, and thus a new printing solution was required. Visutech investigated the pains and challenges, working with OSO Hotwater to overcome these challenges and complexities with a future-proof solution.

The Challenge and Solutions

The Challenge

As the product range of OSO Hotwater expanded and evolved, so did the volume and complexity of their printed documentation. Manuals needed to be regularly updated, produced in small batches, often translated in up

to 23 languages.

Previously, OSO Hotwater were running a toner-based press from another manufacturer, paired with a standard booklet maker solution. The setup couldn’t keep up, lacked speed, struggled with thicker booklets, and forced the team to split single manuals into multiple, stapled sections. This often caused delays on the production floor, as operators could not complete packaging when updated manuals were not ready.

Manual reprints of documentation changes also resulted in waste and rising costs. And when jobs required immediate turnaround, external print suppliers simply weren’t fast or flexible enough.

The Solution

OSO Hotwater turned to Kyocera's TASKalfa Pro 15000c inkjet device, paired with the Plockmatic BF-450e booklet maker.

From day one, the BF-450e’s fast and reliable performance made a clear impact. Its ability to produce high-quality, stapled booklets—up to 50 sheets—meant that most manuals could now be delivered as single, complete documents. This eliminated the confusion and slowdowns caused by handling multiple booklet parts per product.

The ease of use and efficiency also allowed the operator to manage daily printing in under an hour, freeing up time for other responsibilities. “I spend maybe an hour a day running the system — sometimes even less. It’s basically starting the job, loading paper and picking up the finished prints.”

The Results

Increased Uptime

Manuals can now be printed on demand and in precise quantities. This has eliminated the need to pre-stock large volumes, cutting both waste and storage needs.

Reduced Delays in Production

The print team can respond instantly when production lines run short of manuals, avoiding costly downtime or overtime labour.

Improved Document Quality

The BF-450e’s higher capacity for booklet thickness ensures complete documentation in one volume—boosting operator efficiency on the floor.

Color Flexibility with Lower Costs

Switching to inkjet gives the team freedom to reintroduce color in technical manuals—especially for complex diagrams—without increasing cost per page.

“With the Kyocera TASKalfa Pro 15000c and our Plockmatic BF-450e, we can scale and serve future demand — without extra headcount.

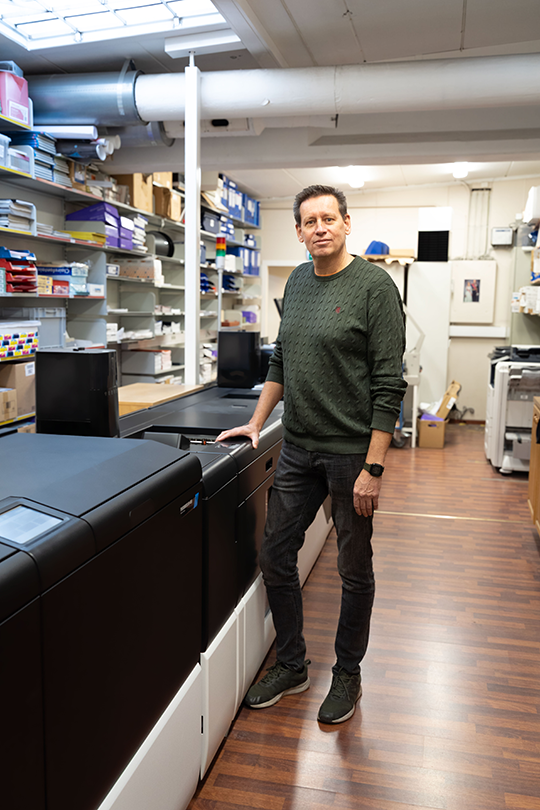

Stig Røed, Technical Documents Developer